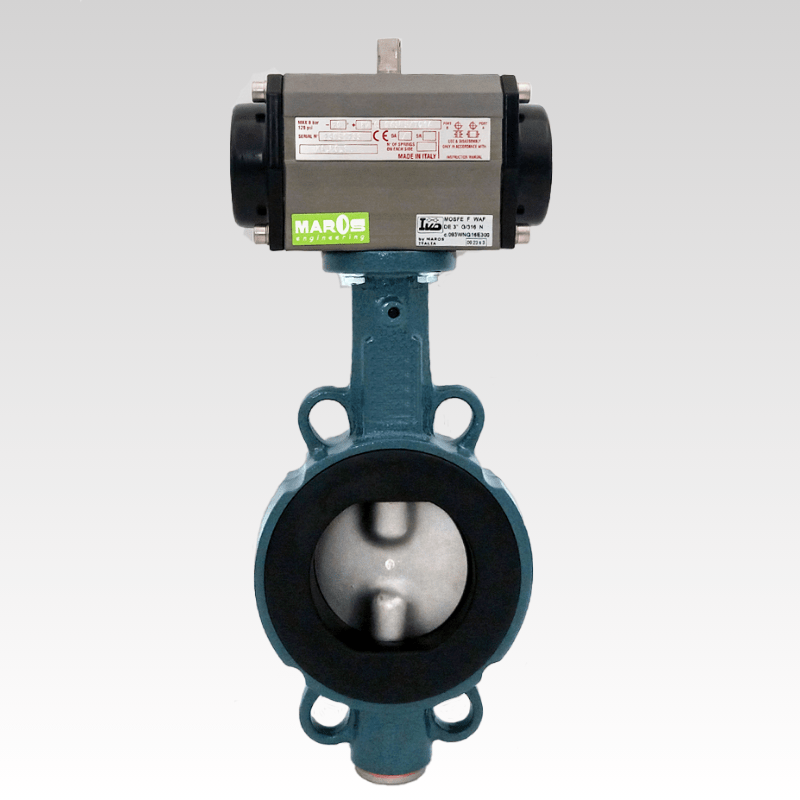

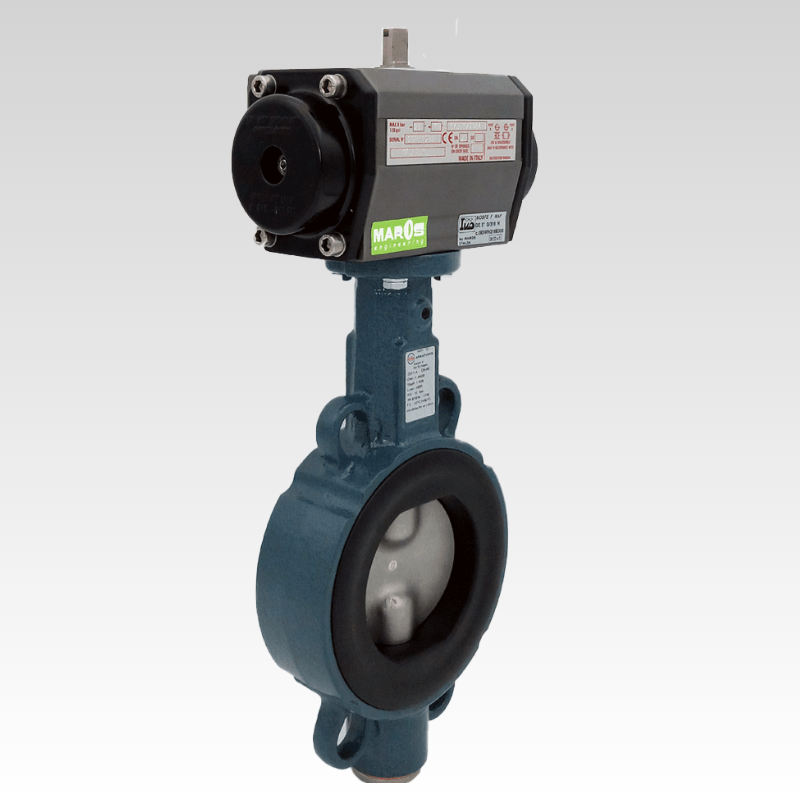

| Sizes | 3/4" - 48” (DN20 – DN1200) |

| Flange accomodations | DIN 2501 PN6/10/16 ANSI B 16.5Classe 150 |

| Fluid temperature | -20°C/ +160°C (depending on pressure, medium and material) |

| Differential pressure | Max ∆p 16 bar |

| Vacuum tightness | Up 0.2 absolute bar (depending on pressure, medium and temperature) |

| Body | Ductile cast iron GGG40 – standard. |

| Disc | Standard CF8M |

| Seals | Nrb, Epdm |

| Versions | Double and single acting |

| Operating temperature | -20°C / +80°C (with standard actuator) |

| Upon request |

| Valve body in aluminium alloy, carbon steel, microcast stainless steel CF8M |

| Steel or stainless steel Aisi 304-316 disc |

| Csm, Fpm, Vsi, Au or Ptfe seals |

| Actuators for different temperature range |